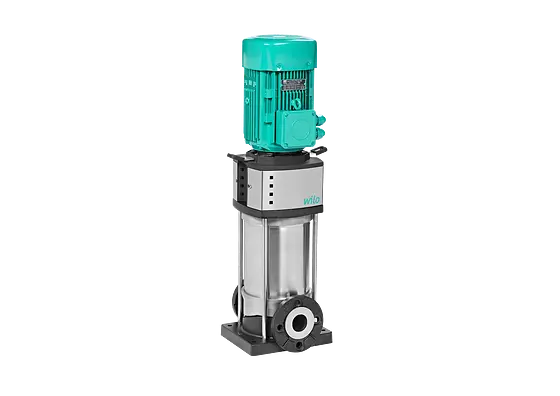

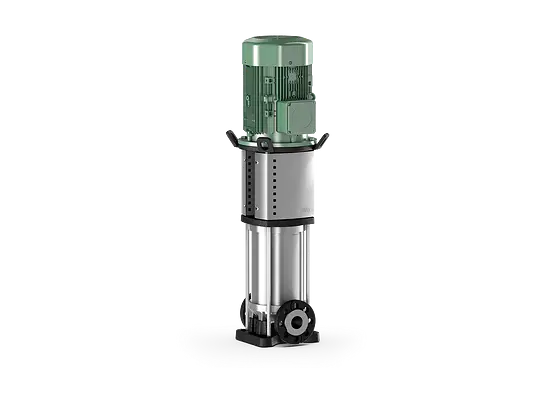

Wilo-Helix V216-2/25/V/KS/400

Design

Non-self-priming, high-efficiency multistage high-pressure centrifugal pump in vertical design with in-line connections

Materials

| Component Name | Construction |

|---|---|

| Pump housing | Stainless steel |

| Impeller | Stainless steel |

| Shaft | Stainless steel |

| Shaft seal | BQ1VGG

|

| Gasket material | FKM |

| Stage chamber material | Stainless steel |

Operating Data

| Operating temperature range & pressure | Value |

|---|---|

| Min. fluid temperature (Tₘᵢₙ) | -15 °C |

| Max. fluid temperature (Tₘₐₓ) | 90 °C |

| Min. ambient temperature (Tₘᵢₙ) | -15 °C |

| Max. ambient temperature (Tₘₐₓ) | 50 °C |

| Maximum operating pressure (Pₙ) | 25 bar |

| Maximum inlet pressure (pᵢₙₗ) | 10 bar |

| Minimum efficiency index (MEI) | ≥0.7 |

Technical data

Fluid temperature range:

➢ Helix V 2 – 16 (EPDM): -30 to 120 °C (130 °C on request)

➢ Helix V 2 – 16 for aggressive media (FKM): -15 to 90 °C

➢ Helix V22 – 52 (EPDM): -30 to 120 °C (130 °C on request)

➢ Helix V22 – 52 for aggressive media (FKM): -15 to 90 °C

Max. operating pressure: 16/25/30 bar

Protection class: IP 55

Max. ambient temperature: +50°C (extended temperature ranges on request)

Available versions:

➢ Helix V 2 – 16: PN 16 with oval flanges, PN 25/PN 40 with compatible round flanges according to ISO 2531 and ISO 7005 (Victaulic coupling or Tricam connection on request)

➢ Helix V 22 – 52: PN 16/PN 25/PN 40 with round flanges according to ISO 2531 and ISO 7005

Application

- Water supply and pressure boosting

- Industrial circulation systems

- Closed cooling circuits

- Fire extinguishing systems

- Washing systems

Scope of delivery

- Helix V high-pressure multistage centrifugal pump

- Installation and operating instructions

- Helix V 2 – 16 (version PN16 with oval flanges): Stainless steel counter flanges with the corresponding screws, nuts and gaskets

Options

- Helix V pumps are available on request with various types of mechanical seals such as porous silicon carbide (Q7Q7) for cooling applications with water-glycol mixture or tungsten carbide/silicon carbide (UQ) for water treatment applications with pure water (conductivity below 3 µS/cm).

- Helix V 2 ... 52 are available with Victaulic connections, Helix V 2 ... 16 are also available with Tri clamp connections (DIN 32676).

- Both stainless steel variants (304 and 316L) can be offered with EPDM or FKM seals.

- New IE4 motors in 50 Hz are available on request to save even more energy.

Your advantages

- Efficiency-optimized, laser-welded 2D/3D hydraulics, flow and degassing optimized

- Corrosion-resistant impellers, guide vanes and stage housings

- Flow and NPSH-optimized pump housing

- Maintenance-friendly design with particularly robust coupling guard

- Drinking water approval for pumps with parts that come in contact with the fluid made of stainless steel (EPDM version)

- 1 YEAR WARRANTY ON MANUFACTURING DEFECTS, IF APPLICABLE

- A 15% HANDLING CHARGE WILL BE APPLIED TO ALL RETURNED ITEMS

- RETURN SHIPPING WILL BE AT THE CUSTOMER'S EXPENSE

- ONLY ITEMS PURCHASED WITHIN 30 DAYS ARE ELIGIBLE FOR RETURN AND RECEIVED IN ORIGINAL PACKING CONDITION

- ALL PRODUCTS ARE SUBJECT TO PRIOR SALE - STOCK NOT HELD

- SUBJECT TO OUR GENERAL TERMS AND CONDITIONS OF SALE

- DELIVERY SCHEDULES WILL BE CONFIRMED UPON RECEIPT OF ORDER

- ALL INFORMATIONS, DESCRIPTIONS, SPECIFICATIONS, IMAGES, AND TERMS ARE SUBJECT TO BE UDPATED WITHOUT PRIOR NOTICE